fresh from the blog

Backyard Aquaponics Systems in Austin, Texas

Introduction to Aquaponics in Austin As springtime ushers in a wave of renewal across Austin, Texas, it's not just the local flora and fauna that experience a revival. Home aquaponics systems, a blend of fish breeding (aquaculture) and water-based plant …

hot topics: aquaponics | organic gardens | backyard chickens | fish | latest

aquaponics

- Backyard Aquaponics Systems in Austin, Texas

- What are the disadvantages of aquaponics?

- Aquaponics Technology: Deep Water Culture (DWC)

- Aquaponics Technology: Media-Based Systems

organic gardens

backyard chickens

fish news

Latest

Backyard Aquaponics Systems in Austin, Texas

Introduction to Aquaponics in Austin As springtime ushers in a wave of …

13 Plants That Will Repel Mosquitoes

The Ultimate Guide to Mosquito-Repelling Plants: Nature's Best Defense Introduction to Mosquito-Repelling …

What are the disadvantages of aquaponics?

Introduction to Aquaponics Aquaponics, a revolutionary method of growing plants and fish …

How to Build a Chicken Coop for Your Backyard Chickens – A Cluckin’ Good Guide

So, you've decided to take the plunge and raise your own backyard …

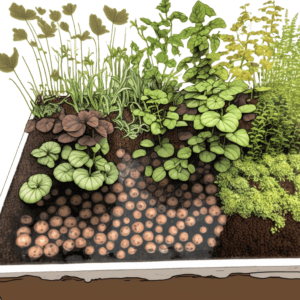

Home In-Ground Vegetable Gardens: A Time-Honored Tradition with Modern Benefits

The practice of growing vegetables in the ground has been around for …

Raised Garden Beds: A Sustainable and Healthy Way to Grow Your Own Food

Gardening has long been a popular hobby and source of fresh produce …

Aquaponics Technology: Deep Water Culture (DWC)

What is a deep water culture (DWC) aquaponics systems Deep water culture …

Aquaponics Technology: Media-Based Systems

Aquaponics is an innovative farming system that combines aquaculture (raising fish) and …

Aquaponics Technology: Nutrient Film Technique (NFT)

What is a Nutrient Film Technique (NFT) system? Nutrient Film Technique (NFT) …

How to Raise Chickens in the City and Keep Your Neighbors Happy

I have been raising chickens in the city for over 15 years, …

Grow Your Own Sustainable Food at Home: A Step-by-Step Guide to Setting up an Aquaponic System

I often get asked two specific questions when it comes to aquaponics. …

Maintaining a Thriving Aquaponic Ecosystem: A Guide to Fish Selection and Keeping Your Fish Healthy

The last thing you want to happen once your garden starts to …

Aquaponics technology: The different systems used in modern aquaponics

Aquaponics is a method of growing plants and raising fish together in …

Aquaponics gardening: The future of sustainable urban farming

Aquaponics gardening is a method of growing plants and raising fish together …

Yellow Bass (Morone mississippiensis)

When it comes to aquaponics systems, size isn't everything. Yellow Bass (Morone …

Hybrid Striped Bass

When it comes to aquaponics systems, Hybrid Bass offer the best of …

White Bass (Morone chrysops)

When it comes to aquaponics systems, few fish are as versatile and …

Container Vegetable Gardens: A Compact and Versatile Solution for Urban Living

For those living in urban areas or with limited outdoor space, the …